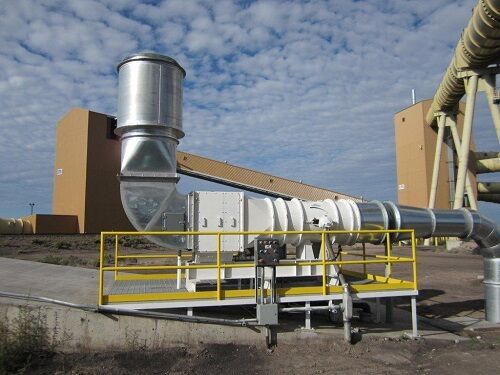

An Englo Type 33 dust extractor is ventilating dust from a coal reclaim tunnel at a power plant. Dust generated at coal feeders is captured and sent to the surface through ductwork connected to the extractor inlet.

Independently tested on PRB coal.

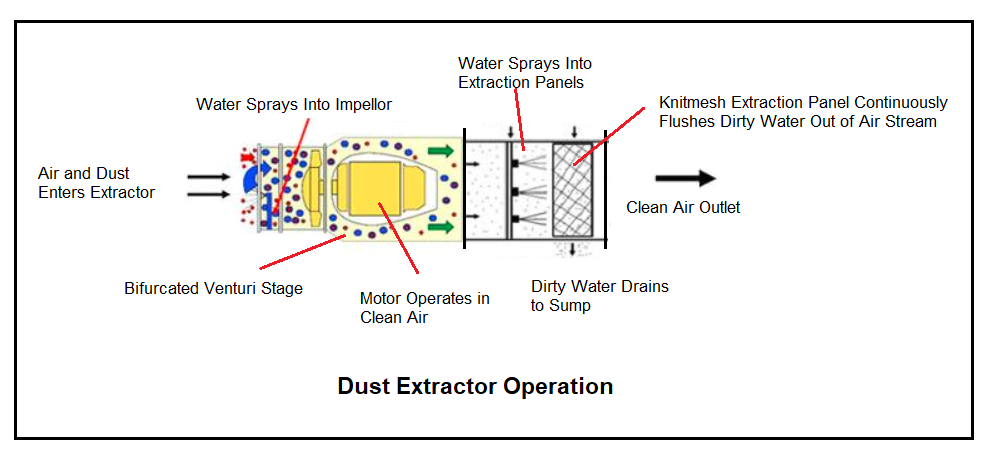

Each dust extractor has an integral axial impellor turbofan that produces the air volume and static pressure required for the exhaust hoods and ductwork system. Water is injected at the impellor inlet where it is spun with high energy to capture extremely fine particulate.

Dirty water is captured with knitmesh panels and discharged to a bottom sump. Dirty effluent drains continuously to a plant drainage system or to a water recirculation filter system. Louvered demister panels capture any overspray from the mesh panels and clean air exits the extractor through an exhaust elbow and silencer stack.

An optional pre-filter inlet box is often used at the inlet to capture about 80% of the incoming dust.

Englo dust extractors include a motor, impellor, knitmesh extraction panels, louver demister panels, water spray headers, water management controls package and electrical controls package. Individual units may include components that are customized for a specific application.

Englo can also design and supply special ventilation equipment such as auxiliary ventilation fans for underground mining and custom packages for tunneling applications. Extractor capacity ranges from 1400 SCFM to over 50,000 SCFM with single units. Additional volume is achieved by installing multiple units in parallel.